Carbonyl Iron Powder: The Ultimate Material for Advanced Tech

Carbonyl iron powder is highly pure and fine-grade substance that is renowned for its remarkable magnetic properties and uniform spherical particles as well as thermal stabilities. It plays an essential role in the development of advanced technologies, such as shielding EMI magnetic components, EMI shielding and metal injection molding and materials that absorb radar. The consistent performance and flexibility make it a popular choice in the electronic, aerospace, defense medical, and other industries. As technology improves, the need for high-quality, precision-engineered and reliable materials such as carbonyl Iron Powder continues to increase, further confirming its place as a key element in the modern world of innovation.

In our blog, our team will describe actually what is a carbonyl iron powder, its composition, key features and applications. We will also explore the pros and cons of iron powder.

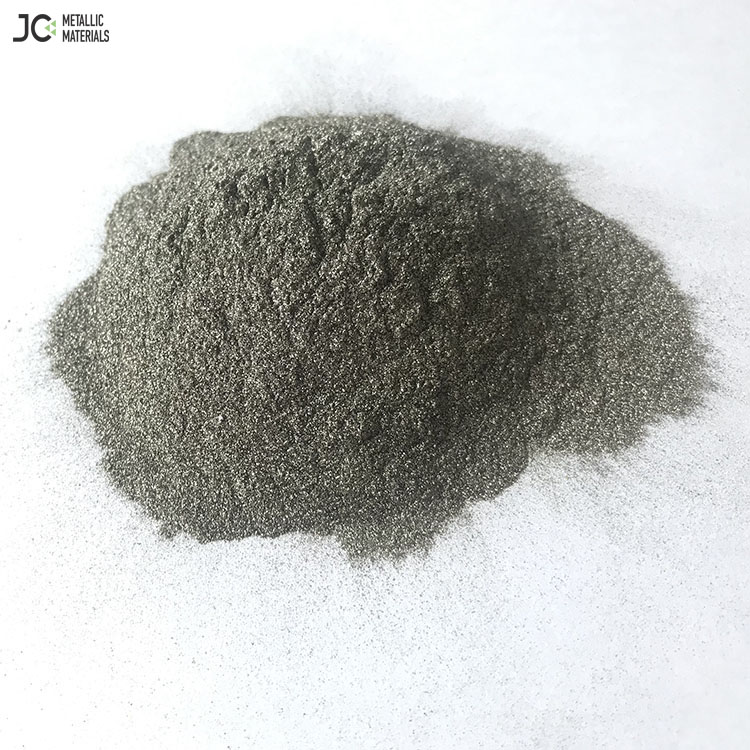

What is a Carbonyl Iron Powder?

Carbonyl Iron Powder can be described as a highly refined type of iron created by the decomposition process from iron pentacarbonyl (Fe(CO)5). This results in highly pure smooth, fine, and spherical iron particles, which typically range between 1 and 10 micron in diameter. Because of its chemical purity, superior magnetic properties and its uniform particle distribution carbonyl iron powder is widely utilized for advanced applications, such as electromagnetic interference (EMI) shielding magnetic cores, magnetic shielding as well as MIM, metal injection molding (MIM) and radar-absorbing materials as well as pharmaceutical-grade iron supplements.

Composition of Carbonyl Iron Powder

Carbonyl Iron Powder is known for its purity, and homogeneous chemical composition. Here’s a comprehensive outline of its most common chemical composition, focusing on pharmaceutical and industrial grades:

(a) Primary Component

- Elemental Iron (Fe): Typically ranges from ≥99.5% to 99.9%

The ultra-pure iron content is the main element of the carbonyl iron powder that ensures an extremely high magnetic permeability, chemical stability and compatibility with delicate applications.

(b) Trace Impurities (Usually <0.5%)

Even though they are found in tiny quantities, trace elements are managed to ensure product quality:

| エレメント | Typical Range (ppm) | Purpose/Impact |

| Carbon (C) | 100–300 ppm | May affect magnetic softness or compressibility |

| Oxygen (O) | 200–600 ppm | From surface oxidation; should be minimized |

| Nitrogen (N) | ≤50 ppm | May be introduced during processing |

| Sulfur (S) | ≤10 ppm | Undesirable for electrical applications |

| Phosphorus (P) | ≤10 ppm | Can affect magnetic and structural properties |

| Other Metals (Ni, Cu, Zn, etc.) | Trace (≤5 ppm) | Should be limited to avoid cross-contamination |

(c) Optional Additives (Application Specific)

Certain grades that are specialized may contain coatings or surface treatments like:

- Silane coating (for better dispersion of composites)

- Coating for pharmaceuticals (for ferro supplements and to improve absorption)

This blend guarantees that carbonyl-iron powder keeps its superior magnetic characteristics as well as flowability and thermal stability, which is vital for the most advanced applications in electronics, defense automobile, healthcare, and defense sectors.

Key Features of Carbonyl Iron Powder

1: Exceptional Purity and Consistency

The carbonyl-iron powder renowned for its purity that is extremely high typically exceeding 99.5 percent. This purity is attained by a controlled chemical vapor decomposition procedure that removes undesirable elements and contaminants. This level of purity guarantees the reliability and durability of delicate applications, especially in those in areas where consistency of chemical or magnetic properties is essential, like in the fields of electronics, pharmaceuticals as well as aerospace manufacture.

2: Spherical Particle Shape

One of the key features of carbonyl iron powders is their uniform, spherical shape. This shape enhances the flowability and compaction of the material which is particularly useful in additive and powder metallurgy manufacturing processes. Spherical particles permit exact control of the density of the packing and material properties during sintering or molding leading to stronger and more stable finished products.

3: Superior Magnetic Properties

Carbonyl iron powder has high magnetic permeability as well as low losses to the core, which makes it ideal for components that require inductive power, such as magnetic cores transformers and EMI shielding material. Its soft magnetic properties allow it to be responsive to magnetic fields with alternating frequency and improve the efficiency of energy in high frequency electrical applications.

4: Fine Particle Size Distribution

The synthesis process is vapor-phase. carbonyl iron powder has an extremely narrow and controlled size distribution that typically ranges between 1 and 10 microns. This exact and reliable distribution is essential in manufacturing processes with high precision such as the metal injection molding (MIM) or small-sized component production, in which consistency and detail resolution are crucial.

5: Excellent Compressibility and Moldability

Because of its ability to flow and the structure of its particles carbonyl iron powder exhibits great moldability and compressibility. This makes it perfect to create dense, intricate forms with a low binder content. It is an important benefit for as well MIM or sintered components manufacturing. This results in smaller shrinkage, higher precision in dimension, and more structure in the finalized parts.

6: Outstanding Thermal Stability

Carbonyl iron powder retains its magnetic and structural properties across a large temperature range. This makes it ideal for applications that require durability in high temperatures like automotive components for engines, defense technologies or industrial devices.

Key Applications of Carbonyl Iron Powder

1: Electromagnetic Interference (EMI) Shielding

Carbonyl iron is commonly utilized in EMI shielding materials because of its magnetic permeability that is superior. It efficiently blocks and absorbs electromagnetic radiation, which makes it vital in aerospace, electronics, and automotive systems to reduce interference in signals and improving the performance of components.

2: Metal Injection Molding (MIM)

In MIM carbonyl iron powder has high flowability, compression and particle homogeneity. These properties allow the creation of high-precision, complex metal parts that have excellent quality and durability perfect for medical equipment and defense components, as well as smaller industrial components.

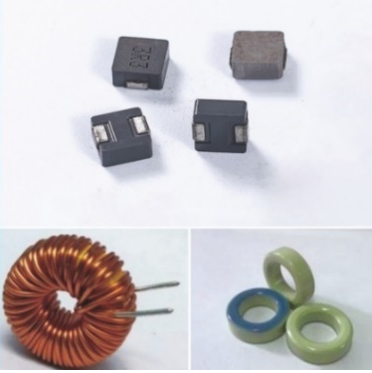

3: Magnetic Core Manufacturing

Due to it’s soft magnet properties and its low loss of the core, carbonyl powder is ideal for the production of magnets with high frequency. It is frequently utilized in inductors, transformers, and chokes in which thermal stability and efficiency as well as magnetic efficiency are crucial performance requirements.

4: Radar Absorbing Materials (RAM)

Carbonyl iron plays an important part in coatings that absorb radar and composites that are used in stealth technology. Its magnetic sensitivity allows it to effectively block radar signals and reduce the risk of detection for military vehicles, aircraft and surveillance systems in all the defense sector.

5: Pharmaceutical Iron Supplements

In the industry of pharmaceuticals, carbonyl iron powder is employed to enhance the iron content due its high bioavailability and its safety profile. The controlled particle size and low absorption make it appropriate for treating iron deficiencies without causing digestive discomfort.

Advantages of Carbonyl Iron Powder

1: High Purity and Consistency

Carbonyl iron powder is of outstanding high chemical purity (typically >99.5 percent) This ensures minimal contamination and dependable behavior of the material which is particularly important in aerospace, electronics and medical applications.

2: Excellent Magnetic Performance

Its excellent characteristics of soft magnets (high permeability and low loss at the core) are ideal for high-frequency components such as transformers, inductors as well as EMI parts for shielding.

3: Uniform Spherical Particles

The powder’s spherical morphology allows an excellent flowability and compressibility that allows for precise metal injection molding as well as additive manufacturing processes that have minimal waste and high accuracy in dimensional measurement.

4: Versatility Across Industries

It is used in everything from pharmaceuticals to automotive components to stealth military coatings as well as electronic parts, carbonyl Iron Powder is a multi-industry hitter.

5: High Compressibility and Moldability

Its physical structure permits compact packing and easy molding into complicated shapes, which makes it ideal for high-precision part production using very little binder content.

Disadvantages of Carbonyl Iron Powder

1: Higher Production Cost

Because of its intricate synthesizing process (thermal breakdown of pentacarbonyl iron) Carbonyl iron powder can be more expensive than conventional reduced or atomized iron powders. This could not work for budget-conscious, high-volume needs.

2: Air Sensitivity During Processing

Its small particle size could cause it to become reactive when exposed to moisture and air in the course of storage or processing which requires controlled environments and protective packing to preserve its stability.

Final Thoughts

Carbonyl iron powder is recognized as an essential element in the development of technology. Its purity is unbeatable, it has a consistent particle size and a superior magnetic properties, it plays an essential role in the creation of EMI shielding as well as 3D printing and precision components. The versatility and adaptability of it to the needs of complex industrial processes makes it an ideal choice for those who need reliability. As the pace of innovation increases and technology advances, carbonyl iron is set to continue to be an essential component of manufacturing at the highest level and in new technological frontiers.

Most Asked Questions About Carbonyl Iron Powder

Q1: What is carbonyl iron powder is used to do?

Answer: It’s commonly employed in EMI shielding magnetic cores, radar-absorbing materials, as well as metal injection molding, specifically in the automotive, electronics and defense industries.

Q2: What is it that makes carbonyl iron powder distinct in comparison to other powders of iron?

Answer: Its spherical shape and extremely high purity and uniform distribution of the particles mark it, making it suitable for high-precision, high-performance and high-performance applications.

Q3: Is carbonyl Iron powder safe for handling?

Answer: Yes, when applied under normal safety guidelines for industry. It is safe, however it must be handled in a well-ventilated area using appropriate personal protective tools due to its small particle size.

Q4: What industries profit the most from carbonyl iron powder?

Answer: Industries like aerospace electronic, automotive and defense are the best especially in areas where material congruity are essential.