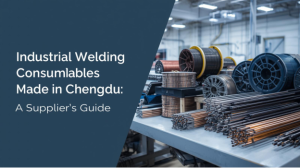

Industrial Welding Consumables Made in Chengdu: A Supplier’s Guide

Chengdu has emerged as a key manufacturing base for 溶接消耗品 in China. The region supports industrial production through advanced facilities and skilled labor. Global demand for welding consumables is rising rapidly. Construction, energy, and heavy engineering industries drive growth. Buyers seek high-quality, cost-effective products. Chinese suppliers, especially in Chengdu, fulfill this demand with consistent quality and reliable international supply chains.

In this article, We will explore

- Why Global Buyers Source Welding Consumables from Chengdu?

- Understanding Welding Consumable

- Manufacturing Processes Used for Welding Consumable

- Comparison Table of Industrial Welding Consumable Processes in Chengdu

- Applications of Welding Consumable Across Industries

- A comprehensive and detailed Buying Guide for Industrial Welding Consumable

- Why Should You Choose Us?

Why Global Buyers Source Welding Consumables from Chengdu?

Global buyers source welding consumable from Chengdu due to cost efficiency and stable manufacturing. The region offers modern production facilities and skilled labor. Suppliers maintain consistent quality. Competitive pricing supports bulk purchasing and long-term industrial supply agreements.

Chengdu suppliers provide flexible OEM options for welding consumable. Export-ready documentation simplifies international trade. Reliable logistics improve delivery timelines. Buyers value responsive communication and scalable production. These factors make Chengdu a preferred sourcing destination for global industrial welding needs.

Understanding Welding Consumables

Welding consumables include electrodes, wires, and fluxes used to join metals. They ensure strong, durable, and precise welds. High-quality consumables improve industrial efficiency, reduce defects, and support applications in construction, energy, automotive, and heavy machinery sectors worldwide.

Manufacturing Processes Used for Welding Consumable

Welding consumables in Chengdu use advanced machinery and skilled labor. Production ensures high-quality, durable, precise, and consistent products meeting global industrial standards.

1: Electrode Coating Process

Electrode coating applies a protective layer to ensure smooth arcs. It improves weld quality, prevents spatter, and meets international industrial welding standards consistently.

2: Wire Drawing Process

Wire drawing creates uniform welding wires with precise diameters. Accurate dimensions improve welding performance, and consistency, ideal for pipelines, heavy machinery, and large-scale industrial projects.

3: Flux Production Process

Flux is chemically formulated to stabilize welding arcs. Proper flux production ensures clean welds, minimal defects, and enhanced penetration for energy, oil and gas industries.

4: Heat Treatment Process

Heat treatment strengthens welding consumables through controlled heating and cooling. It improves durability, and performance for high-stress industrial environments and structural steel applications.

5: Quality Testing & Inspection

Each consumable undergoes strict quality inspections. Visual, chemical, and mechanical tests ensure ISO and AWS compliance, defect-free products for global industrial buyers.

You Can Learn More: Tungsten Carbide Vs Titanium Carbide: How to Choose the Right One?

Comparison Table of Industrial Welding Consumable Processes in Chengdu

This comparison table outlines the core industrial welding electrodes processes used in Chengdu-based manufacturing facilities. It highlights how each process improves product consistency, performance, and buyer confidence for global industrial procurement.

| Process | Output | Key Feature | Buyer Benefit |

| Electrode Coating | Smooth, consistent electrodes | Uniform arc & coating | Reduces welding defects, improves efficiency |

| Wire Drawing | Precise welding wires | Accurate diameter control | Ideal for bulk industrial orders |

| Flux Production | Stable flux compounds | Chemical stability | Minimizes spatter, improves weld quality |

| Heat Treatment | Strong, durable consumables | Enhanced mechanical properties | Long-lasting performance in heavy applications |

| Quality Testing | Verified compliant products | ISO & AWS standard checks | Assures global buyers of reliability |

| Packaging & Inspection | Export-ready consumables | Protective and labeled | Safe delivery, extended shelf life |

Applications of Welding Consumable Across Industries

Welding electrodes from Chengdu serve diverse industrial applications. They ensure strong, durable welds in construction, energy, and manufacturing sectors. High-quality products meet global industrial standards and buyer requirements.

- Construction Industry:Used for structural steel frameworks and building projects

- Shipbuilding Industry:Essential for welding hulls and heavy ship components

- Oil & Gas Sector:Supports pipelines, rigs, and refinery equipment welding

- Heavy Machinery Manufacturing:Strengthens machinery and equipment through durable welds

- Automotive Industry:Ensures precision welding in vehicle frames and components

You Can Learn More: Step-by-Step B2B Guide: How to Import Brass Metal Powder?

A Professional Sourcing and Supplier Guide for Welding Consumable

Choosing the right welding consumable is crucial for industrial applications. This guide helps buyers understand types, quality standards, material composition, and supplier selection for safe, durable, and efficient welding operations.

1: Identify Industrial Requirements

Determine the type of welding needed for your industry. Consider metal types, project scale, and environmental conditions. Correct requirements ensure optimal consumable selection and long-lasting welds.

2: Choose the Right Welding Consumable Type

Select electrodes, wires, fluxes, or filler metals based on application. Each type serves specific welding methods, strength requirements, and industrial standards to meet project demands.

3: Check Material Composition

Review alloy composition, carbon, nickel, chromium, and flux additives. Proper material ensures strength, durability, corrosion resistance, and consistent welding performance for heavy-duty industrial applications.

4: Evaluate Quality Standards

Verify ISO, AWS, and international certifications. High-quality consumables meet global industrial benchmarks, reducing defects and ensuring safety, reliability, and long-term performance in demanding welding operations.

5: Assess Supplier Capabilities

Choose suppliers with production capacity, technical support, export experience, and OEM customization. Reliable suppliers ensure consistent delivery, quality, and long-term industrial partnerships.

6: Consider Packaging & Logistics

Inspect packaging, labeling, and shipment options. Safe, export-ready packaging prevents damage during transit, maintains shelf life, and ensures consumables reach global buyers in optimal condition.

7: Plan Budget & Cost Efficiency

Compare price-to-quality ratios, bulk discounts, and long-term sourcing options. Efficient budgeting ensures high-performance consumables without compromising quality, supporting cost-effective industrial operations.

You Can Learn More: Why Boron Carbide Powder is Essential For Hard Material Processing?

Why Should You Choose Chengdu Jinchun Metallic Materials Co. Ltd.?

Chengdu Jinchun Metallic Materials Co. Ltd. delivers high-quality welding consumables with consistent performance. Our advanced production, skilled workforce, and reliable supply chains make us a trusted partner for global industrial buyers.

- Consistent Quality:Reliable, defect-free welding consumable for all projects.

- Custom OEM Options:Tailored products to match your specifications.

- Reliable Bulk Supply:Timely delivery for large industrial orders.

- Safe Export Packaging:Protected products with proper documentation.

- Expert Technical Support:Guidance to optimize welding efficiency.

Final Thoughts

Reliable, high-quality welding consumables ensure consistent performance across industrial projects. Advanced manufacturing, skilled labor, and strict quality control enhance durability. Buyers benefit from OEM support, safe export packaging, and efficient supply, making Chengdu a trusted global sourcing hub.

Most Asked Questions

Q1: Are Chengdu welding consumable suitable for heavy industry?

Answer: Yes, Chengdu welding consumables are designed for heavy industrial applications. They offer high strength, durability, and consistent performance, making them ideal for construction, shipbuilding, pipelines, and other demanding sectors worldwide.

Q2: Can welding consumable be customized or OEM branded?

Answer: Yes, most Chengdu suppliers provide OEM and private-label options. Buyers can request custom specifications, alloy compositions, and packaging, ensuring products meet industrial standards and branding requirements for international markets.

Q3: What types of welding consumable are commonly produced?

Answer: Chengdu manufacturers produce electrodes, welding wires, fluxes, filler metals, and specialty alloy consumables. These types support heavy machinery, energy, construction, automotive, and shipbuilding applications with reliable industrial performance.

Q4: How fast can Chengdu suppliers deliver bulk orders?

Answer: Lead times depend on order size and production schedules. Most Chengdu suppliers maintain reliable timelines for bulk welding consumables, ensuring consistent supply for industrial projects and global shipping requirements.

Q5: Are these consumables eco-friendly?

Answer: Some Chengdu suppliers produce environmentally friendly welding consumables, including low-smoke fluxes and reduced-emission materials. These meet modern environmental regulations while maintaining strength, durability, and industrial performance for global buyers.