potassium titanate

Caractéristiques du produit:

Potassium titanate is a new type of additive, and our company’s products use special processes to completely solve the problem of moisture absorption in potassium titanate products. The main indicators of our company’s products are superior to foreign products.

| Nom de la marque | Jinchun |

| Origine | Chine |

| Nom du produit | Potassium titanate |

| Application | Core additives for welding materials,Friction material composite filler |

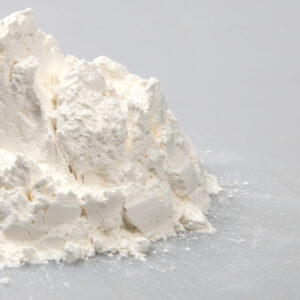

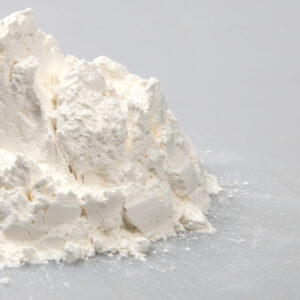

| Forme | granular or powder |

| Couleur | White or beige |

| Taille | Can be booked according to customer needs |

| Standard | GB/T 19001-2016/ISO9001 : 2015 |

| La pureté | K₂TiO3: 90%~95% |

| Matériau | K₂TiO3 |

| Emballage | 25KG composite or cardboard box |

DÉTAILS DU PRODUIT

DÉTAILS DU PRODUIT

Caractère du produit

Potassium titanate is a new type of additive, and our company’s products use special processes to completely solve the problem of moisture absorption in potassium titanate products. The main indicators of our company’s products are superior to foreign products.

2. cahier des charges

Potassium titanate

3.Pictures of Powder

Photos de la production et des essais :

Photos de la production et des essais :

4.Application

Potassium titanate powder is different from crystal whiskers, nanotubes and other forms. Its core characteristics are controllable particle size, good dispersibility, easy to composite with various substrates, and high processing adaptability. It retains the heat resistance, wear resistance, insulation, corrosion resistance, low thermal conductivity and other properties commonly used in the potassium titanate family. Its aspect ratio enhancement without crystal whiskers is emphasized, and its applications focus on functional fillers, composite additives, coating materials, industrial additives, precursors and other directions.

Core additives for welding materials

1.Core function: Improve the flowability, spreadability, and deslagging of slag, significantly enhancing the quality of weld formation; Stabilize the arc, reduce welding spatter, and improve the process adaptability of AC/DC welding rods; Refine the grain size of the weld seam, enhance the mechanical properties and corrosion resistance of the welded joint.

2.Specific applications: Main ingredients for low hydrogen type welding rods, dual-use carbon steel welding rods, and stainless steel welding rod coating; Composite filler for submerged arc welding flux; Core additives for flux cored welding wire, replacing some titanium dioxide and rutile, reducing welding material costs while improving performance.

Friction material composite filler

1.Core function: Synergistic whiskers enhance the wear resistance and heat resistance of friction plates (stable above 350 ℃), reduce the wear of mating parts, and improve the formability of friction materials, avoiding uneven dispersion of whiskers during mixing and compression molding.

2.Specific applications: automotive brake pads, brake shoes, clutch pads; The brake lining of construction machinery and rail transit vehicles is often compounded with carbon black, barium sulfate, glass fiber, and other materials.

Ceramic/refractory material raw materials

1.Ceramic raw materials: added to alumina and zirconia ceramic slurries to reduce the sintering temperature of ceramics, refine ceramic grains, improve the toughness and thermal shock resistance of ceramic products, and applied to high-temperature ceramic components and ceramic tool blanks.

2.Refractory filling material: Composite with aluminum silicate and refractory cement to prepare refractory bricks and refractory castables for industrial kilns, improving the wear resistance, erosion resistance, and thermal insulation of refractory materials, and extending the service life of kilns.

Thermal insulation coating/filler

1.Raw materials for thermal insulation coatings: composite with organic silicon, epoxy resin, and ceramic based adhesives to prepare high-temperature resistant thermal insulation coatings; Applied to the inner walls of industrial kilns, surfaces of metallurgical equipment, peripheral components of rocket engines, and thermal insulation coatings for automotive exhaust pipes to reduce heat loss.

2.Building insulation filler: added to exterior wall insulation mortar and roof insulation coating, using high infrared reflectivity to block solar radiation, reduce indoor energy consumption, and adapt to energy-saving building materials.

3.Electronic insulation filler: added to electrical insulation glue and insulation plastic to improve the insulation resistance and arc resistance of materials, applied to motor stator insulation layer, electrical switch housing, and wire and cable sheath modification.

4.Application

Potassium titanate powder is different from crystal whiskers, nanotubes and other forms. Its core characteristics are controllable particle size, good dispersibility, easy to composite with various substrates, and high processing adaptability. It retains the heat resistance, wear resistance, insulation, corrosion resistance, low thermal conductivity and other properties commonly used in the potassium titanate family. Its aspect ratio enhancement without crystal whiskers is emphasized, and its applications focus on functional fillers, composite additives, coating materials, industrial additives, precursors and other directions.

Core additives for welding materials

1.Core function: Improve the flowability, spreadability, and deslagging of slag, significantly enhancing the quality of weld formation; Stabilize the arc, reduce welding spatter, and improve the process adaptability of AC/DC welding rods; Refine the grain size of the weld seam, enhance the mechanical properties and corrosion resistance of the welded joint.

2.Specific applications: Main ingredients for low hydrogen type welding rods, dual-use carbon steel welding rods, and stainless steel welding rod coating; Composite filler for submerged arc welding flux; Core additives for flux cored welding wire, replacing some titanium dioxide and rutile, reducing welding material costs while improving performance.

Friction material composite filler

1.Core function: Synergistic whiskers enhance the wear resistance and heat resistance of friction plates (stable above 350 ℃), reduce the wear of mating parts, and improve the formability of friction materials, avoiding uneven dispersion of whiskers during mixing and compression molding.

2.Specific applications: automotive brake pads, brake shoes, clutch pads; The brake lining of construction machinery and rail transit vehicles is often compounded with carbon black, barium sulfate, glass fiber, and other materials.

Ceramic/refractory material raw materials

1.Ceramic raw materials: added to alumina and zirconia ceramic slurries to reduce the sintering temperature of ceramics, refine ceramic grains, improve the toughness and thermal shock resistance of ceramic products, and applied to high-temperature ceramic components and ceramic tool blanks.

2.Refractory filling material: Composite with aluminum silicate and refractory cement to prepare refractory bricks and refractory castables for industrial kilns, improving the wear resistance, erosion resistance, and thermal insulation of refractory materials, and extending the service life of kilns.

Thermal insulation coating/filler

1.Raw materials for thermal insulation coatings: composite with organic silicon, epoxy resin, and ceramic based adhesives to prepare high-temperature resistant thermal insulation coatings; Applied to the inner walls of industrial kilns, surfaces of metallurgical equipment, peripheral components of rocket engines, and thermal insulation coatings for automotive exhaust pipes to reduce heat loss.

2.Building insulation filler: added to exterior wall insulation mortar and roof insulation coating, using high infrared reflectivity to block solar radiation, reduce indoor energy consumption, and adapt to energy-saving building materials.

3.Electronic insulation filler: added to electrical insulation glue and insulation plastic to improve the insulation resistance and arc resistance of materials, applied to motor stator insulation layer, electrical switch housing, and wire and cable sheath modification.

| Nom/ Type | Élément | TiO2 | K2O | S | P |

| KT-102 | Résultat(%) | 55%~65% | 28%~32% | ≤0.02% | ≤0.02% |

| KT-575 | Résultat(%) | 73%~79% | 19.5%~22.5% | ≤0.02% | ≤0.02% |

| KT-106 | Résultat(%) | 65%~75% | 17%~22% | ≤0.02% | ≤0.02% |

| KT-101 | Résultat(%) | 50%~60% | 35%~40% | ≤0.02% | ≤0.02% |

| KT-108 | Résultat(%) | 68%~78% | 16.5%~17.5% | ≤0.025% | ≤0.025% |

| KT-109 | Résultat(%) | 83.5%~86.5% | 13.5%~16.5% | ≤0.025% | ≤0.025% |

Photos de la production et des essais :

Photos de la production et des essais :

4.Application

Potassium titanate powder is different from crystal whiskers, nanotubes and other forms. Its core characteristics are controllable particle size, good dispersibility, easy to composite with various substrates, and high processing adaptability. It retains the heat resistance, wear resistance, insulation, corrosion resistance, low thermal conductivity and other properties commonly used in the potassium titanate family. Its aspect ratio enhancement without crystal whiskers is emphasized, and its applications focus on functional fillers, composite additives, coating materials, industrial additives, precursors and other directions.

Core additives for welding materials

1.Core function: Improve the flowability, spreadability, and deslagging of slag, significantly enhancing the quality of weld formation; Stabilize the arc, reduce welding spatter, and improve the process adaptability of AC/DC welding rods; Refine the grain size of the weld seam, enhance the mechanical properties and corrosion resistance of the welded joint.

2.Specific applications: Main ingredients for low hydrogen type welding rods, dual-use carbon steel welding rods, and stainless steel welding rod coating; Composite filler for submerged arc welding flux; Core additives for flux cored welding wire, replacing some titanium dioxide and rutile, reducing welding material costs while improving performance.

Friction material composite filler

1.Core function: Synergistic whiskers enhance the wear resistance and heat resistance of friction plates (stable above 350 ℃), reduce the wear of mating parts, and improve the formability of friction materials, avoiding uneven dispersion of whiskers during mixing and compression molding.

2.Specific applications: automotive brake pads, brake shoes, clutch pads; The brake lining of construction machinery and rail transit vehicles is often compounded with carbon black, barium sulfate, glass fiber, and other materials.

Ceramic/refractory material raw materials

1.Ceramic raw materials: added to alumina and zirconia ceramic slurries to reduce the sintering temperature of ceramics, refine ceramic grains, improve the toughness and thermal shock resistance of ceramic products, and applied to high-temperature ceramic components and ceramic tool blanks.

2.Refractory filling material: Composite with aluminum silicate and refractory cement to prepare refractory bricks and refractory castables for industrial kilns, improving the wear resistance, erosion resistance, and thermal insulation of refractory materials, and extending the service life of kilns.

Thermal insulation coating/filler

1.Raw materials for thermal insulation coatings: composite with organic silicon, epoxy resin, and ceramic based adhesives to prepare high-temperature resistant thermal insulation coatings; Applied to the inner walls of industrial kilns, surfaces of metallurgical equipment, peripheral components of rocket engines, and thermal insulation coatings for automotive exhaust pipes to reduce heat loss.

2.Building insulation filler: added to exterior wall insulation mortar and roof insulation coating, using high infrared reflectivity to block solar radiation, reduce indoor energy consumption, and adapt to energy-saving building materials.

3.Electronic insulation filler: added to electrical insulation glue and insulation plastic to improve the insulation resistance and arc resistance of materials, applied to motor stator insulation layer, electrical switch housing, and wire and cable sheath modification.

4.Application

Potassium titanate powder is different from crystal whiskers, nanotubes and other forms. Its core characteristics are controllable particle size, good dispersibility, easy to composite with various substrates, and high processing adaptability. It retains the heat resistance, wear resistance, insulation, corrosion resistance, low thermal conductivity and other properties commonly used in the potassium titanate family. Its aspect ratio enhancement without crystal whiskers is emphasized, and its applications focus on functional fillers, composite additives, coating materials, industrial additives, precursors and other directions.

Core additives for welding materials

1.Core function: Improve the flowability, spreadability, and deslagging of slag, significantly enhancing the quality of weld formation; Stabilize the arc, reduce welding spatter, and improve the process adaptability of AC/DC welding rods; Refine the grain size of the weld seam, enhance the mechanical properties and corrosion resistance of the welded joint.

2.Specific applications: Main ingredients for low hydrogen type welding rods, dual-use carbon steel welding rods, and stainless steel welding rod coating; Composite filler for submerged arc welding flux; Core additives for flux cored welding wire, replacing some titanium dioxide and rutile, reducing welding material costs while improving performance.

Friction material composite filler

1.Core function: Synergistic whiskers enhance the wear resistance and heat resistance of friction plates (stable above 350 ℃), reduce the wear of mating parts, and improve the formability of friction materials, avoiding uneven dispersion of whiskers during mixing and compression molding.

2.Specific applications: automotive brake pads, brake shoes, clutch pads; The brake lining of construction machinery and rail transit vehicles is often compounded with carbon black, barium sulfate, glass fiber, and other materials.

Ceramic/refractory material raw materials

1.Ceramic raw materials: added to alumina and zirconia ceramic slurries to reduce the sintering temperature of ceramics, refine ceramic grains, improve the toughness and thermal shock resistance of ceramic products, and applied to high-temperature ceramic components and ceramic tool blanks.

2.Refractory filling material: Composite with aluminum silicate and refractory cement to prepare refractory bricks and refractory castables for industrial kilns, improving the wear resistance, erosion resistance, and thermal insulation of refractory materials, and extending the service life of kilns.

Thermal insulation coating/filler

1.Raw materials for thermal insulation coatings: composite with organic silicon, epoxy resin, and ceramic based adhesives to prepare high-temperature resistant thermal insulation coatings; Applied to the inner walls of industrial kilns, surfaces of metallurgical equipment, peripheral components of rocket engines, and thermal insulation coatings for automotive exhaust pipes to reduce heat loss.

2.Building insulation filler: added to exterior wall insulation mortar and roof insulation coating, using high infrared reflectivity to block solar radiation, reduce indoor energy consumption, and adapt to energy-saving building materials.

3.Electronic insulation filler: added to electrical insulation glue and insulation plastic to improve the insulation resistance and arc resistance of materials, applied to motor stator insulation layer, electrical switch housing, and wire and cable sheath modification.