Spherical Metal Powders Tantalum (Ta) Powder

Product Character:

The tantalum implant formed by 3D printing has the closest elastic modulus to human cartilage tissue, making it the most ideal orthopedic implant material. Spherical tantalum powder is suitable for processes such as laser/electron beam additive manufacturing, hot isostatic pressing, laser cladding, and hot/cold spraying.

| Brand Name | Jinchun |

| Origin | China |

| Product name | Spherical Tantalum powder |

| Application | Orthopedic implants by 3d printing, laser/electron beam additive manufacturing, hot isostatic pressing, laser cladding, and hot/cold spraying |

| Shape | Powder |

| Color | Metal gray |

| Size | 15~53μm, 53~150μm, 15~45μm, 45~106μm, 1~10μm, 5~25μm, or customized. |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Purity | Ta: 99.95% min |

| Material | Ta |

| Packing | Vacuum packing |

PRODUCT DETAIL

PRODUCT DETAIL

Product Character

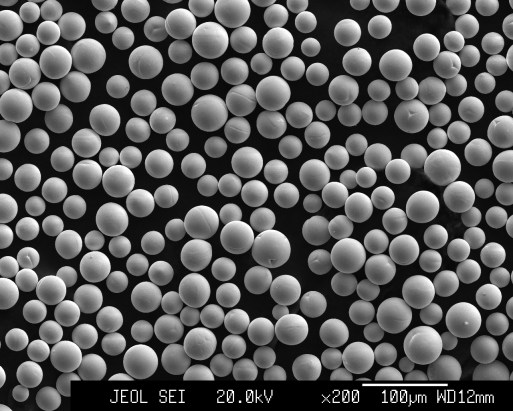

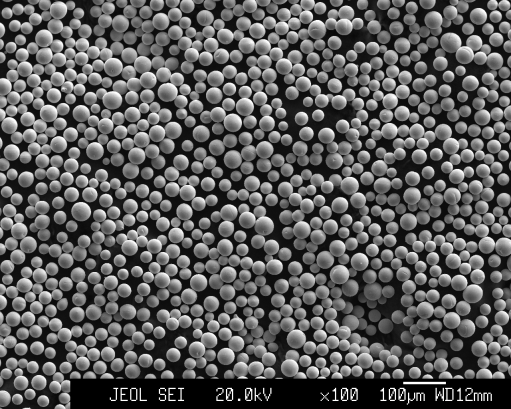

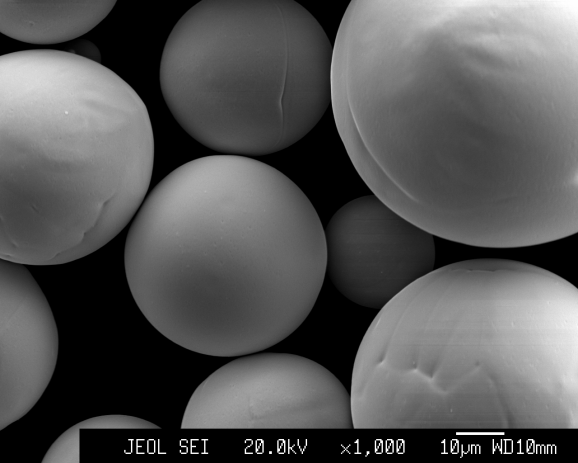

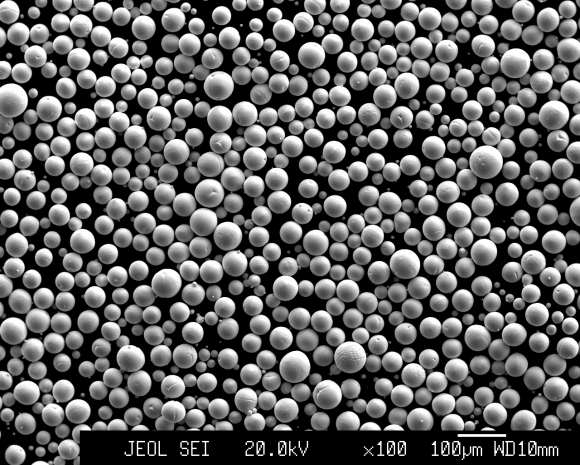

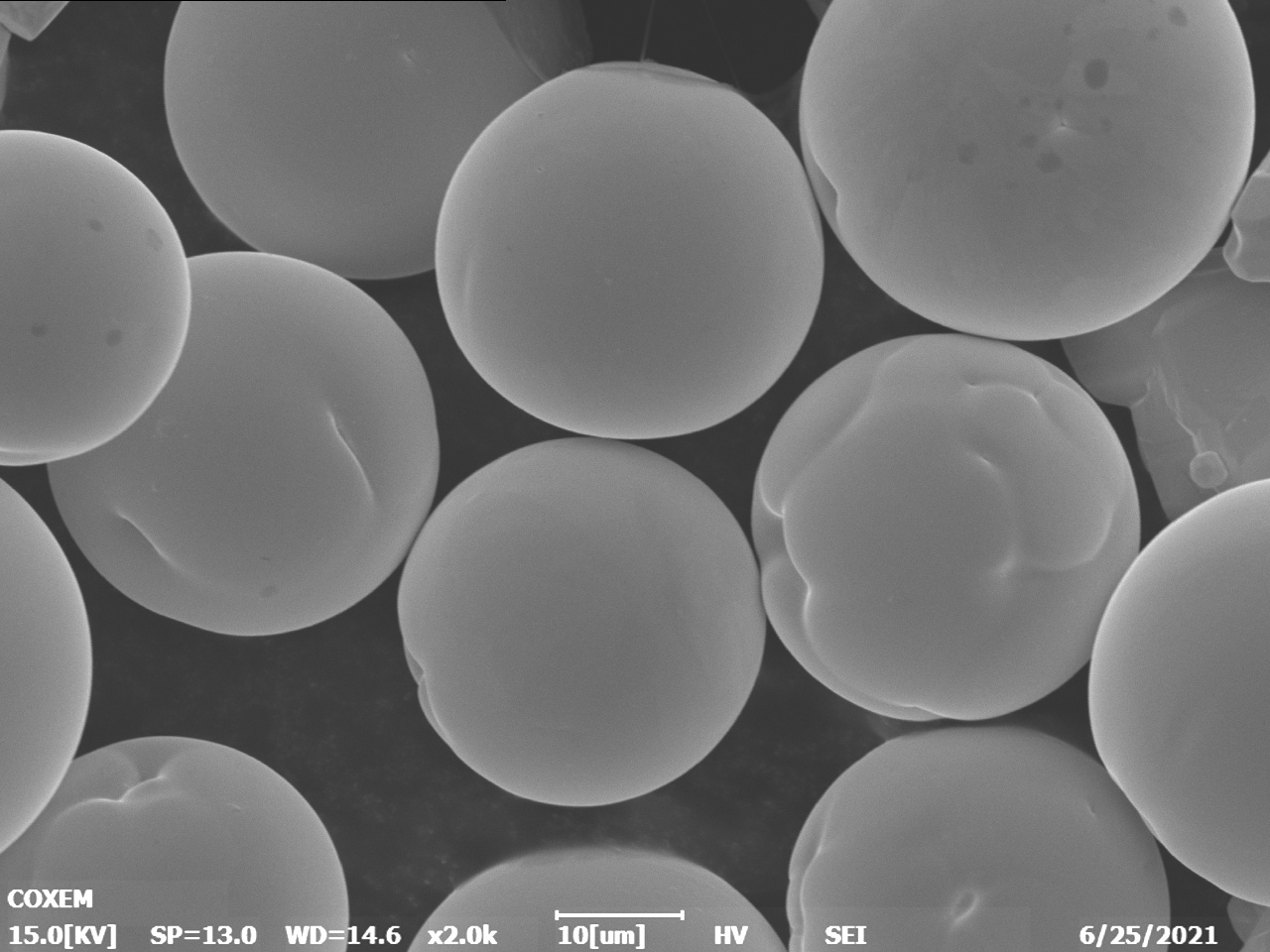

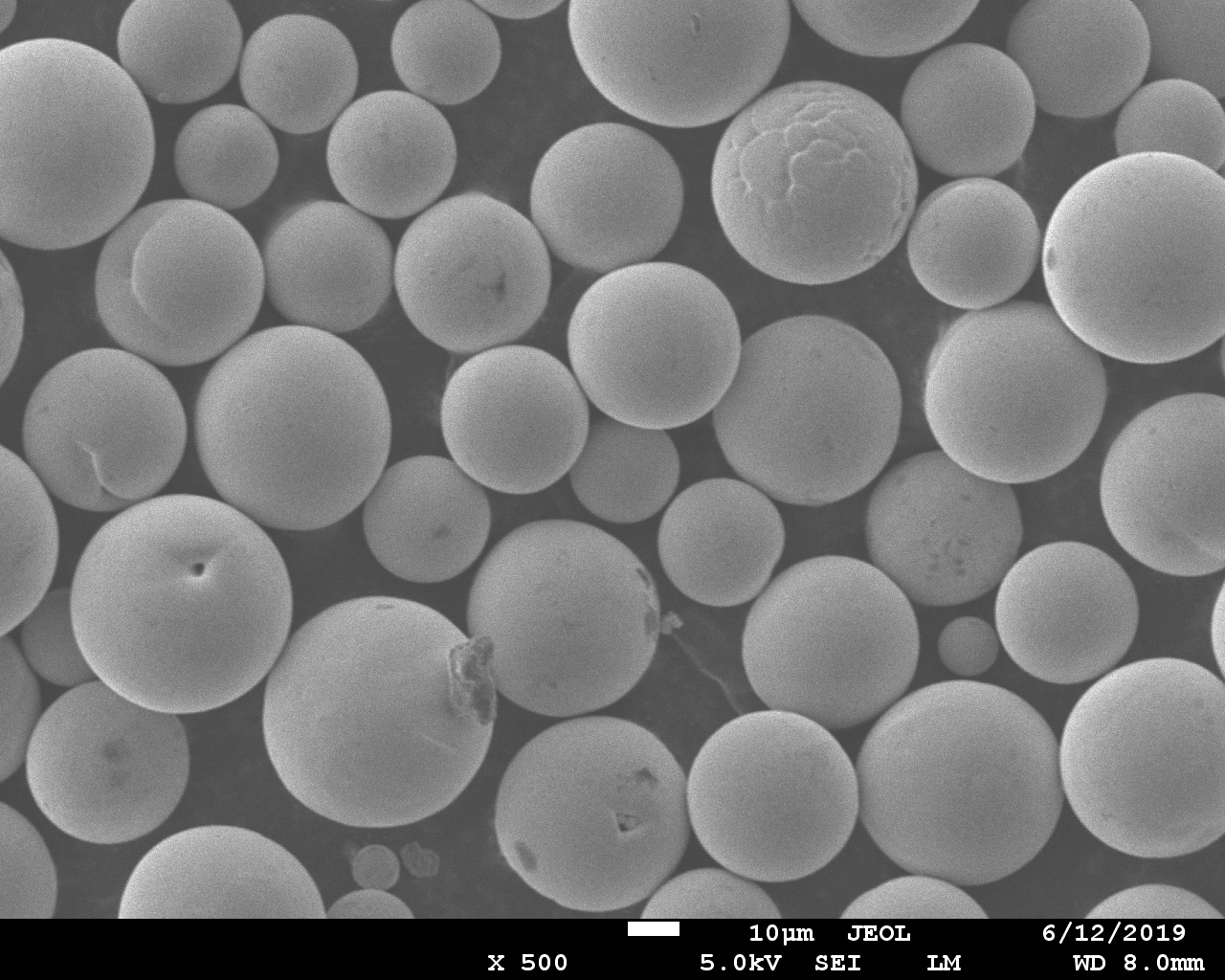

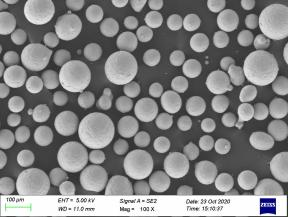

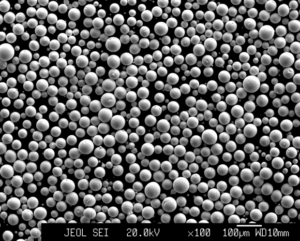

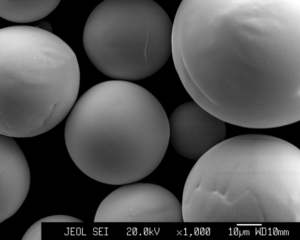

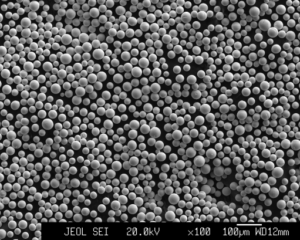

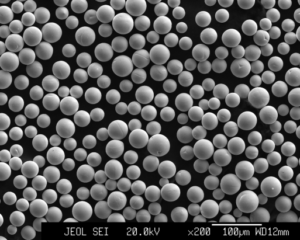

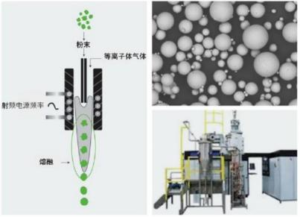

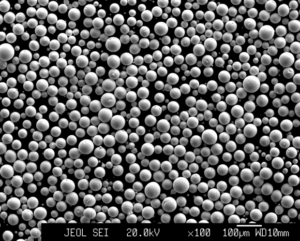

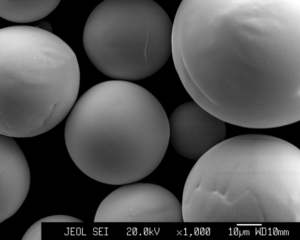

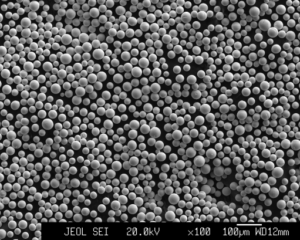

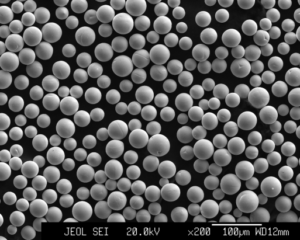

Spherical tantalum powder is manufactured using RF plasma spheroidization technology, which has the characteristics of high purity, low oxygen content, high sphericity, smooth surface, no satellites, uniform particle size distribution, excellent flowability, high loose density and tap density.

2.Specification

Spherical Tantalum Powder

3.Pictures of Powder SEM morphology

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

| Chemical Composition (wt.%) | ||||||||

| Element | Ta | Fe | Ni | Nb | W | Mo | Si | Ti |

| Standard | ≥99.95 | ≤0.002 | ≤0.001 | ≤0.001 | ≤0.010 | ≤0.0125 | ≤0.002 | ≤0.002 |

| typical | ≥99.95 | 0.0013 | 0.0003 | 0.0005 | 0.001 | 0.001 | 0.002 | 0.0005 |

| Element | C | H | N | O(option 1) | O (option 2) | |||

| Standard | ≤0.030 | ≤0.050 | ||||||

| typical | 0.0005 | 0.0008 | 0.002 | 0.01 | 0.042 | |||

| Spherical Tantalum powder | 15~53μm Particle Size Distribution | Flow Rate (sec. for 50 g) | Apparent density (g/cm3) | Tap density (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 15~25 | 20~30 | 40~50 | ≤25 | ≥4.2 | ≥4.9 |

| typical | 15.01μm | 28.81μm | 45.96μm | 5.98 | 9.61 | 10.8 |

| Spherical Tantalum powder | 53~150μm Particle Size Distribution | Flow Rate (sec. for 50 g) | Apparent density (g/cm3) | Tap density (g/cm3) | ||

| D10 | D50 | D90 | ||||

| Standard | 60~70 | 100~110 | 150~160 | ≤25 | ≥4.2 | ≥4.9 |

| typical | 61.48μm | 104.9μm | 154.8μm | 4.8 | 7.58 | 9.2 |

Pictures of Production and Test:

Pictures of Production and Test:

4.Application

4.Application

- The tantalum implant formed by 3D printing has the closest elastic modulus to human cartilage tissue, making it the most ideal orthopedic implant material. Spherical tantalum powder is suitable for processes such as laser/electron beam additive manufacturing, hot isostatic pressing, laser cladding, and hot/cold spraying.