Niobium chromium alloy

Produktcharakter:

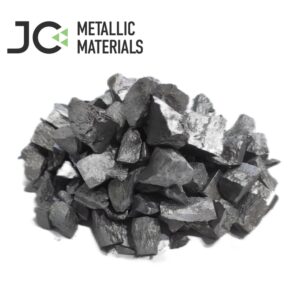

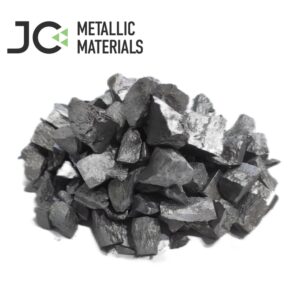

Niobium chromium alloy is a metal material with excellent properties, high strength and good toughness. It is usually obtained by powder metallurgy process, which involves mixing niobium powder, chromium powder and other raw materials, followed by ball milling, compression molding, sintering and aging treatment to obtain niobium chromium alloy material.

| Markenname | Jinchun |

| Herkunft | China |

| Name des Produkts | Niobium chromium alloy |

| Anmeldung | Aerospace field,Energy sector,Chemical engineering field,Medical field,Electronics field |

| Form | Blocks and powders |

| Farbe | Silver gray |

| Größe | 60mesh |

| Standard | GB/T 19001-2016/ISO9001: 2015 |

| Reinheit | Nb80Cr20: 77%-83% |

| Material | Nb80Cr20 |

| Verpacken | Ton bags, iron drums, vacuum packaging |

PRODUKT DETAIL

PRODUKT DETAIL

Produkt Charakter

Niobium chromium alloy is a metal material with excellent properties, high strength and good toughness. It is usually obtained by powder metallurgy process, which involves mixing niobium powder, chromium powder and other raw materials, followed by ball milling, compression molding, sintering and aging treatment to obtain niobium chromium alloy material.

2.Spezifikation

Niobium chromium alloy

3.Pictures of Powder

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

Niobium chromium alloy is a high-performance alloy material composed of niobium as the matrix and chromium and other alloying elements (such as titanium, zirconium, tungsten, etc.) added. With its unique advantages such as excellent high-temperature strength, good oxidation resistance, excellent corrosion resistance, and low density, it has been widely and significantly applied in multiple fields that require strict material performance, providing key material support for technological progress and product upgrades in related industries

Aerospace field

1.Aircraft engine components: During the operation of aircraft engines, components such as combustion chambers and turbine blades need to withstand long-term erosion from high temperature, high pressure, and high-speed airflow, requiring extremely high temperature performance of materials.

2.Spacecraft structural components and thermal protection systems: Spacecraft will face extreme temperature changes and complex space environments when entering the atmosphere and operating in orbit.

Energy sector

1.In the field of nuclear energy: In nuclear reactors, fuel cladding tubes need to withstand high temperature, high pressure, and strong radiation environments, while also having good corrosion resistance to prevent nuclear fuel leakage.

2.In the field of solar energy, with the continuous development of solar technology, concentrated solar power (CSP) systems have received widespread attention due to their efficient energy conversion efficiency.

Chemical engineering field

1.Chemical equipment components: During the chemical production process, equipment such as reaction vessels, heat exchangers, and pipelines are exposed to corrosive media for a long time, which can easily cause corrosion damage and affect the normal operation of production and the service life of equipment.

2.Catalyst carrier: In some chemical catalytic reactions, the catalyst needs to be attached to a specific carrier to achieve the best catalytic effect. At the same time, the carrier also needs to have good high temperature resistance and chemical stability to adapt to the harsh conditions of the catalytic reaction

Medical field

1.Medical device components: In some surgical instruments and medical equipment, such as orthopedic surgical instruments, dental treatment instruments, etc., materials with good corrosion resistance and mechanical properties are required to ensure the safety and reliability of the instruments.

2.Biological implant materials: With the continuous development of biomedical engineering, biological implant materials are playing an increasingly important role in treating various diseases and improving human functions.

Electronics field

1.Electronic packaging materials: Electronic packaging materials need to have good thermal conductivity and sealing properties to ensure that the heat generated by electronic components during operation can be dissipated in a timely manner, while preventing impurities such as moisture and dust from the external environment from entering the interior of the package, affecting the performance and service life of electronic components.

2.High temperature electronic component electrodes: Electronic components that operate in high-temperature environments (such as high-temperature sensors, high-temperature thermocouples, etc.) require electrode materials with good high-temperature resistance and conductivity to ensure that the electronic components can function properly in high-temperature environments.

4.Anwendung

Niobium chromium alloy is a high-performance alloy material composed of niobium as the matrix and chromium and other alloying elements (such as titanium, zirconium, tungsten, etc.) added. With its unique advantages such as excellent high-temperature strength, good oxidation resistance, excellent corrosion resistance, and low density, it has been widely and significantly applied in multiple fields that require strict material performance, providing key material support for technological progress and product upgrades in related industries

Aerospace field

1.Aircraft engine components: During the operation of aircraft engines, components such as combustion chambers and turbine blades need to withstand long-term erosion from high temperature, high pressure, and high-speed airflow, requiring extremely high temperature performance of materials.

2.Spacecraft structural components and thermal protection systems: Spacecraft will face extreme temperature changes and complex space environments when entering the atmosphere and operating in orbit.

Energy sector

1.In the field of nuclear energy: In nuclear reactors, fuel cladding tubes need to withstand high temperature, high pressure, and strong radiation environments, while also having good corrosion resistance to prevent nuclear fuel leakage.

2.In the field of solar energy, with the continuous development of solar technology, concentrated solar power (CSP) systems have received widespread attention due to their efficient energy conversion efficiency.

Chemical engineering field

1.Chemical equipment components: During the chemical production process, equipment such as reaction vessels, heat exchangers, and pipelines are exposed to corrosive media for a long time, which can easily cause corrosion damage and affect the normal operation of production and the service life of equipment.

2.Catalyst carrier: In some chemical catalytic reactions, the catalyst needs to be attached to a specific carrier to achieve the best catalytic effect. At the same time, the carrier also needs to have good high temperature resistance and chemical stability to adapt to the harsh conditions of the catalytic reaction

Medical field

1.Medical device components: In some surgical instruments and medical equipment, such as orthopedic surgical instruments, dental treatment instruments, etc., materials with good corrosion resistance and mechanical properties are required to ensure the safety and reliability of the instruments.

2.Biological implant materials: With the continuous development of biomedical engineering, biological implant materials are playing an increasingly important role in treating various diseases and improving human functions.

Electronics field

1.Electronic packaging materials: Electronic packaging materials need to have good thermal conductivity and sealing properties to ensure that the heat generated by electronic components during operation can be dissipated in a timely manner, while preventing impurities such as moisture and dust from the external environment from entering the interior of the package, affecting the performance and service life of electronic components.

2.High temperature electronic component electrodes: Electronic components that operate in high-temperature environments (such as high-temperature sensors, high-temperature thermocouples, etc.) require electrode materials with good high-temperature resistance and conductivity to ensure that the electronic components can function properly in high-temperature environments.

| Name/Typ | Element | Nb | Cr | C | Si | P | S | Al | Fe |

| Nb80Cr20 | Standard(%) | 77-83 | 16-22 | ≤0.05 | ≤0.5 | ≤0.03 | ≤0.03 | ≤1.0 | ≤0.5 |

| Ergebnis(%) | |||||||||

| Name/Typ | Element | Zr | Fe | N | Si | P | S | Al | C |

| Nb64Cr36 | Standard(%) | 62-66 | 34-38 | ≤0.05 | ≤0.5 | ≤0.03 | ≤0.03 | ≤1.0 | ≤0.5 |

| Ergebnis(%) | |||||||||

| Name/Typ | Element | Zr | Fe | N | Si | P | S | Al | C |

| Nb25Cr75 | Standard(%) | 23-27 | 73-77 | ≤0.05 | ≤0.5 | ≤0.03 | ≤0.03 | ≤1.0 | ≤0.5 |

| Ergebnis(%) |

Bilder von Produktion und Test:

Bilder von Produktion und Test:

4.Anwendung

Niobium chromium alloy is a high-performance alloy material composed of niobium as the matrix and chromium and other alloying elements (such as titanium, zirconium, tungsten, etc.) added. With its unique advantages such as excellent high-temperature strength, good oxidation resistance, excellent corrosion resistance, and low density, it has been widely and significantly applied in multiple fields that require strict material performance, providing key material support for technological progress and product upgrades in related industries

Aerospace field

1.Aircraft engine components: During the operation of aircraft engines, components such as combustion chambers and turbine blades need to withstand long-term erosion from high temperature, high pressure, and high-speed airflow, requiring extremely high temperature performance of materials.

2.Spacecraft structural components and thermal protection systems: Spacecraft will face extreme temperature changes and complex space environments when entering the atmosphere and operating in orbit.

Energy sector

1.In the field of nuclear energy: In nuclear reactors, fuel cladding tubes need to withstand high temperature, high pressure, and strong radiation environments, while also having good corrosion resistance to prevent nuclear fuel leakage.

2.In the field of solar energy, with the continuous development of solar technology, concentrated solar power (CSP) systems have received widespread attention due to their efficient energy conversion efficiency.

Chemical engineering field

1.Chemical equipment components: During the chemical production process, equipment such as reaction vessels, heat exchangers, and pipelines are exposed to corrosive media for a long time, which can easily cause corrosion damage and affect the normal operation of production and the service life of equipment.

2.Catalyst carrier: In some chemical catalytic reactions, the catalyst needs to be attached to a specific carrier to achieve the best catalytic effect. At the same time, the carrier also needs to have good high temperature resistance and chemical stability to adapt to the harsh conditions of the catalytic reaction

Medical field

1.Medical device components: In some surgical instruments and medical equipment, such as orthopedic surgical instruments, dental treatment instruments, etc., materials with good corrosion resistance and mechanical properties are required to ensure the safety and reliability of the instruments.

2.Biological implant materials: With the continuous development of biomedical engineering, biological implant materials are playing an increasingly important role in treating various diseases and improving human functions.

Electronics field

1.Electronic packaging materials: Electronic packaging materials need to have good thermal conductivity and sealing properties to ensure that the heat generated by electronic components during operation can be dissipated in a timely manner, while preventing impurities such as moisture and dust from the external environment from entering the interior of the package, affecting the performance and service life of electronic components.

2.High temperature electronic component electrodes: Electronic components that operate in high-temperature environments (such as high-temperature sensors, high-temperature thermocouples, etc.) require electrode materials with good high-temperature resistance and conductivity to ensure that the electronic components can function properly in high-temperature environments.

4.Anwendung

Niobium chromium alloy is a high-performance alloy material composed of niobium as the matrix and chromium and other alloying elements (such as titanium, zirconium, tungsten, etc.) added. With its unique advantages such as excellent high-temperature strength, good oxidation resistance, excellent corrosion resistance, and low density, it has been widely and significantly applied in multiple fields that require strict material performance, providing key material support for technological progress and product upgrades in related industries

Aerospace field

1.Aircraft engine components: During the operation of aircraft engines, components such as combustion chambers and turbine blades need to withstand long-term erosion from high temperature, high pressure, and high-speed airflow, requiring extremely high temperature performance of materials.

2.Spacecraft structural components and thermal protection systems: Spacecraft will face extreme temperature changes and complex space environments when entering the atmosphere and operating in orbit.

Energy sector

1.In the field of nuclear energy: In nuclear reactors, fuel cladding tubes need to withstand high temperature, high pressure, and strong radiation environments, while also having good corrosion resistance to prevent nuclear fuel leakage.

2.In the field of solar energy, with the continuous development of solar technology, concentrated solar power (CSP) systems have received widespread attention due to their efficient energy conversion efficiency.

Chemical engineering field

1.Chemical equipment components: During the chemical production process, equipment such as reaction vessels, heat exchangers, and pipelines are exposed to corrosive media for a long time, which can easily cause corrosion damage and affect the normal operation of production and the service life of equipment.

2.Catalyst carrier: In some chemical catalytic reactions, the catalyst needs to be attached to a specific carrier to achieve the best catalytic effect. At the same time, the carrier also needs to have good high temperature resistance and chemical stability to adapt to the harsh conditions of the catalytic reaction

Medical field

1.Medical device components: In some surgical instruments and medical equipment, such as orthopedic surgical instruments, dental treatment instruments, etc., materials with good corrosion resistance and mechanical properties are required to ensure the safety and reliability of the instruments.

2.Biological implant materials: With the continuous development of biomedical engineering, biological implant materials are playing an increasingly important role in treating various diseases and improving human functions.

Electronics field

1.Electronic packaging materials: Electronic packaging materials need to have good thermal conductivity and sealing properties to ensure that the heat generated by electronic components during operation can be dissipated in a timely manner, while preventing impurities such as moisture and dust from the external environment from entering the interior of the package, affecting the performance and service life of electronic components.

2.High temperature electronic component electrodes: Electronic components that operate in high-temperature environments (such as high-temperature sensors, high-temperature thermocouples, etc.) require electrode materials with good high-temperature resistance and conductivity to ensure that the electronic components can function properly in high-temperature environments.