Types, Properties & Applications of Tantalum Powder

Tantalum Powder is a gray, fine metallic substance that is derived from tantalum iron. It is extremely resistant to corrosion and excellent thermal conductivity. It is used extensively in electronic components, capacitors as well as medical implant. It aids in miniaturization of electronic devices with high performance. It is also useful in the fields of aerospace and chemical manufacturing of equipment. The biocompatibility of it makes it perfect for surgical procedures. It is available in different dimensions and levels of purity. It is a reliable material that performs well in extreme conditions.

Looking for a premium tantalum powder suitable for defense, medical, or electronic applications? Chengdu Jinchun Metallic Materials Co., Ltd. provides specific grades with precision particle control, perfect for the engineers, sourcing agents or industrial materials buyers around the world.

Types of Tantalum Powder

1: Capacitor Grade Tantalum Powder

It is used in capacitors is renowned for its large surface area and its extremely tiny particle size. This kind is developed for the manufacture of solid tantalum capacitors. These are used extensively in automotive, consumer electronics, control systems, as well as telecommunications.

- The typical purity:95% or higher

- Mesh Size:In general, less than 325 mesh

- Application: Tantalum capacitors small-format electronic devices and implanted medical device.

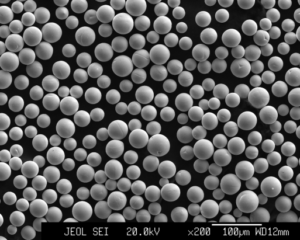

2: Spherical Tantalum Powder

The spherical powder is distinguished by its uniform, round particles that enhance the density of packing and flowability. This kind of powder is widely employed for additive manufacturing (3D printing) as well as metal injection molding.

- Production Method:Plasma atomization or gas atomization

- Applications: Aerospace components, medical implants, customized tooling

3: Nodular Tantalum Powder

Nodular tantalum powder has the shape of a sponge, a porous structure with a large surface area which is ideal for fabrication of anodes. It’s comparable to capacitor-grade powder, but it is optimized to meet specific electrolyte needs.

- Application:Electrolytic capacitors storage components with high energy density

4: Granular Tantalum Powder

This is a softer version of tantalum used in metallurgy and as a feedstock for alloying processes. It is not as sensitive and also has a smaller surface area than capacitor-grade varieties.

- Applications for superalloys:Alloying, chemical equipment and sputtering targets

5: High Purity Tantalum Powder

It is used in applications that require absolute purity, like medical grade components and semiconductor manufacturing.

- Purity Level: Up to 99.999%

- Applications:Thin-film Deposition, optical coatings, medical implants

Properties of Tantalum Powder

1: Corrosion Resistance

It is almost invulnerable against chemical attacks at ambient temperature from all acids. It is extremely resistant to hydrochloric, nitric and sulfuric acids. This makes it ideal for chemical processing environments.

2: High Melting Point

Tantalum has melting points of around 3017degC (5463degF) which makes it ideal for high-temperature applications which include aerospace turbines as well as heat-resistant coatings.

3: Electrical Conductivity

Although it isn’t as conductory as silver or copper but it maintains its electrical properties even under mechanical or thermal stress, which is vital in microelectronics.

4: Biocompatibility

Tantalum is bioinert and non-toxic that means it doesn’t interact negatively with tissues of the body. This makes it a preferred material for implant, bone grafts and dental applications.

5: Ductility and Workability

This powder can be compressed and sintered into intricate designs while maintaining high mechanical strength. Its versatility is a benefit in the field of additive manufacturing and medical devices that are custom-designed.

6: Thermal Conductivity

Tantalum is a good thermal conductor which allows it to disperse heat efficiently in both industrial and electronic thermal systems.

Applications of Tantalum Powder

1: Electronics Industry

It is vital in the manufacturing of tantalum capacitors. These provide solid electrical properties, a longevity, and capacitance, even in tiny sizes.

- Use Cases: Tablets, smartphones laptops, hearing aids, laptops, GPS systems

- Advantages:High volumetric efficiency, resistance to high temperature and humidity

2: Aerospace and Defense

Because of its resistance to temperatures of high and the corrosive environment, tantalum is utilized in the production of high-performance alloys as well as components for spacecraft, aircraft, in addition to military-grade hardware.

- Uses:jet engine components and thermal barriers, rocket nozzles and corrosion-resistant coatings

- Advantages:Increased structural integrity even at extreme temperatures

3: Medical and Dental

Tantalum’s biocompatibility has resulted in extensive use in medical devices, notably in dentistry and orthopedics.

- Application: Bone plates dental prosthetics for the cranial area and spinal Fusion devices

- Advantages:Low tissue reaction, high osteointegration, MRI compatibility

4: Additive Manufacturing (3D Printing)

The spherical shape of the powder is perfect for additive manufacturing, providing the highest quality, density and customisation for complicated parts with complex geometries.

- Industries:Aerospace, medical, defense, tooling

- Advantages:Part design that is custom Reduced waste, lighter construction

5: Chemical Processing Industry

The chemical sector uses tantalum parts composed of powder are used in equipment that is exposed to harsh chemicals and high pressures.

- Applications: These include heat exchangers, reactor liners, condensers and pumps, as well as valve Linings

- Advantages:Longer life span of equipment Low maintenance, no risk of contamination

6: Superalloys and Metallurgy

This powder is alloyed cobalt, nickel and other elements in order to make superalloys for turbine blades as well as combustion chambers.

- Advantages:Strong and creep resistance, the resistance to oxidation

- Industries: Gas turbines, power plants, marine engineering

7: Thin Film and Coatings

It can be vaporized or sputtered into thin films for optics and electronics. They function as diffusion barriers, resistors and anti-corrosion layers.

- Industries: Such as solar, semiconductor and optical

- Advantages:Control of layers with precision and enhanced durability, as well as conductivity stability

8: Research and Nuclear Applications

Tantalum’s ability to absorb neutrons is ideal for nuclear reactors as well as shielding. Research institutes also utilize powder to conduct high-energy tests as well as prototype development.

- Applications:Reactor components, lab-scale sintering, neutron radiography

- Advantages:Radiation shielding Structural stability, predictable in stress

Conclusion

Tantalum powder has a unique combination of thermal, electrical and chemical properties, making it an essential ingredient in all industries. It can be used to enhance medical implants, creating miniaturized electronic devices or even enduring the harshest environmental conditions in chemical factories, tantalum continues to provide support for advanced engineering and technological advancement. As a trusted supplier, Chengdu Jinchun Metallic Materials Co. Ltd. provides premium quality, finely-graded and high-purity tantalum powders that are suitable for the most challenging applications on the world market.

Most Asked Questions

Q1: Why is tantalum powder used for high-temperature or corrosive conditions?

Answer: This powder is resistant to extreme temperatures (melting point of 3017degC) and virtually all acids, including hydrochloric as well as the nitric. This is why it is ideal for use in aerospace, chemical processing as well as defense where endurance and durability under pressure are crucial.

Q2: How is biocompatibility making tantalum powder useful for dental and medical use?

Answer: Tantalum is bioinert and safe and causes no adverse reactions within our bodies. Its osseointegration capabilities and MRI ability make it suitable for bone implants as well as spinal fusion devices and dental prosthetics that offer long-term results.

Q3: What makes tantalum powder ideal for coatings with high-tech and additive manufacturing?

Answer: The powder is spherical and provides great performance and flowability in 3D printing. It is also a good choice for thin-film coatings for optics, semiconductors and solar panels. It provides durability, conductivity, as well as resistance to corrosion.

https://www.jinchunmetal.com/?s=Tantalum+Powder