제품 캐릭터

GH5188 is a solid solution strengthened cobalt based high-temperature alloy, which is strengthened by adding 14% tungsten to give the alloy excellent high-temperature thermal strength. At the same time, adding a high content of chromium and trace amounts of La gives the alloy good high-temperature oxidation resistance. Compared to nickel based high-temperature alloys, GH5188 has more good creep resistance, thermal corrosion resistance, fatigue resistance, and high temperature strength. GH5188 has excellent formability, welding and other process properties, making it suitable for manufacturing parts for aircraft engines that require high strength below 980 ℃ and anti-oxidation below 1000 ℃. In the 1980s, GH5188 alloy was applied to components such as vortex plates and flame deflectors in turboshaft eight aircraft engines. Currently, some aircraft engines use GH5188 alloy sheets to prepare high-temperature components such as combustion chamber walls, outer walls, and sealing plates.

2.사양

GH5188 powder

| 화학 성분(중량 %) |

| 요소 |

C |

Cr |

Ni |

Co |

La |

W |

Si |

Fe |

| 표준 |

0.05~0.15 |

20.0~24.0 |

20.0~24.0 |

Bal. |

0.03~0.12 |

13.0~16.0 |

0.2~0.5 |

≤3.0 |

| typical |

0.11 |

22.33 |

22.17 |

Bal. |

0.06 |

14.91 |

0.44 |

0.49 |

| 요소 |

Mn |

P |

S |

Cu |

B |

O |

N |

|

| 표준 |

≤1.25 |

≤0.02 |

≤0.015 |

≤0.070 |

≤0.015 |

≤0.030 |

≤0.030 |

|

| typical |

0.26 |

0.006 |

0.006 |

0.021 |

0.0092 |

0.017 |

0.01 |

|

| GH5188 |

15~53μm

입자 크기 분포 |

유량

(50g의 경우 초) |

겉보기 밀도(g/cm3) |

탭 밀도(g/cm3) |

|

D10 |

D50 |

D90 |

|

|

|

| 표준 |

15~25 |

30~40 |

50~60 |

≤25 |

≥4.55 |

≥5.30 |

| typical |

22.2μm |

35.6μm |

55.0μm |

17 |

4.57 |

5.33 |

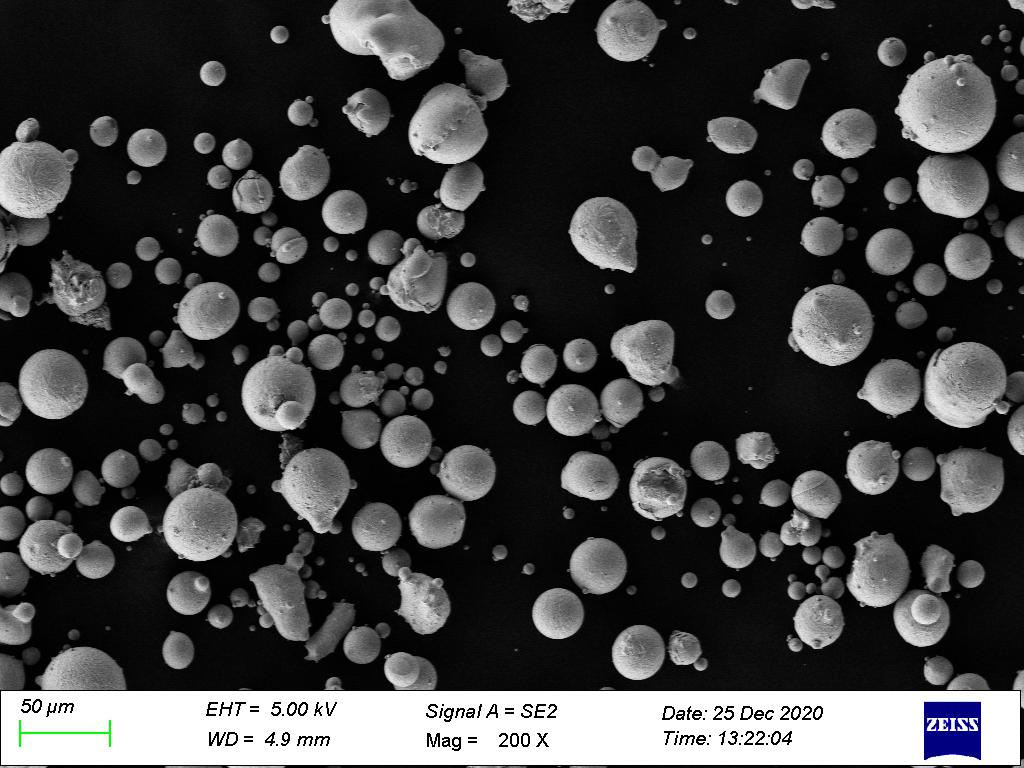

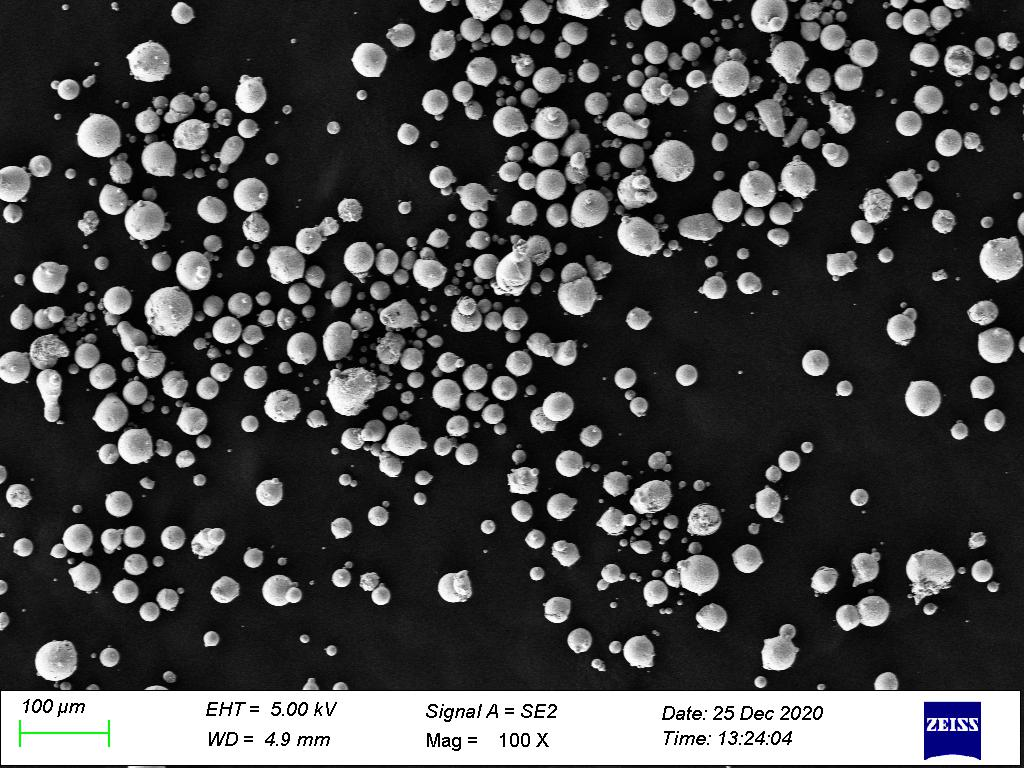

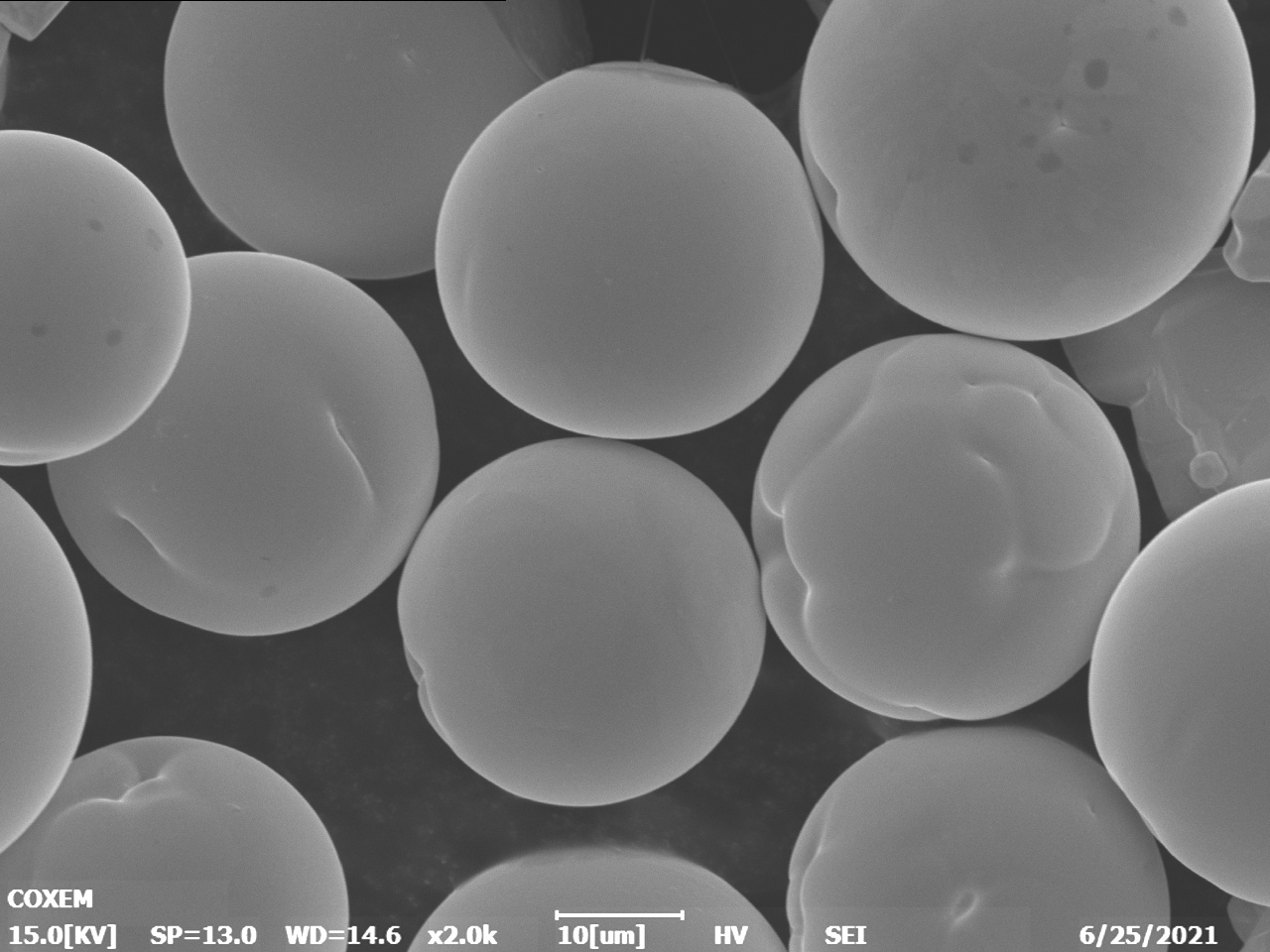

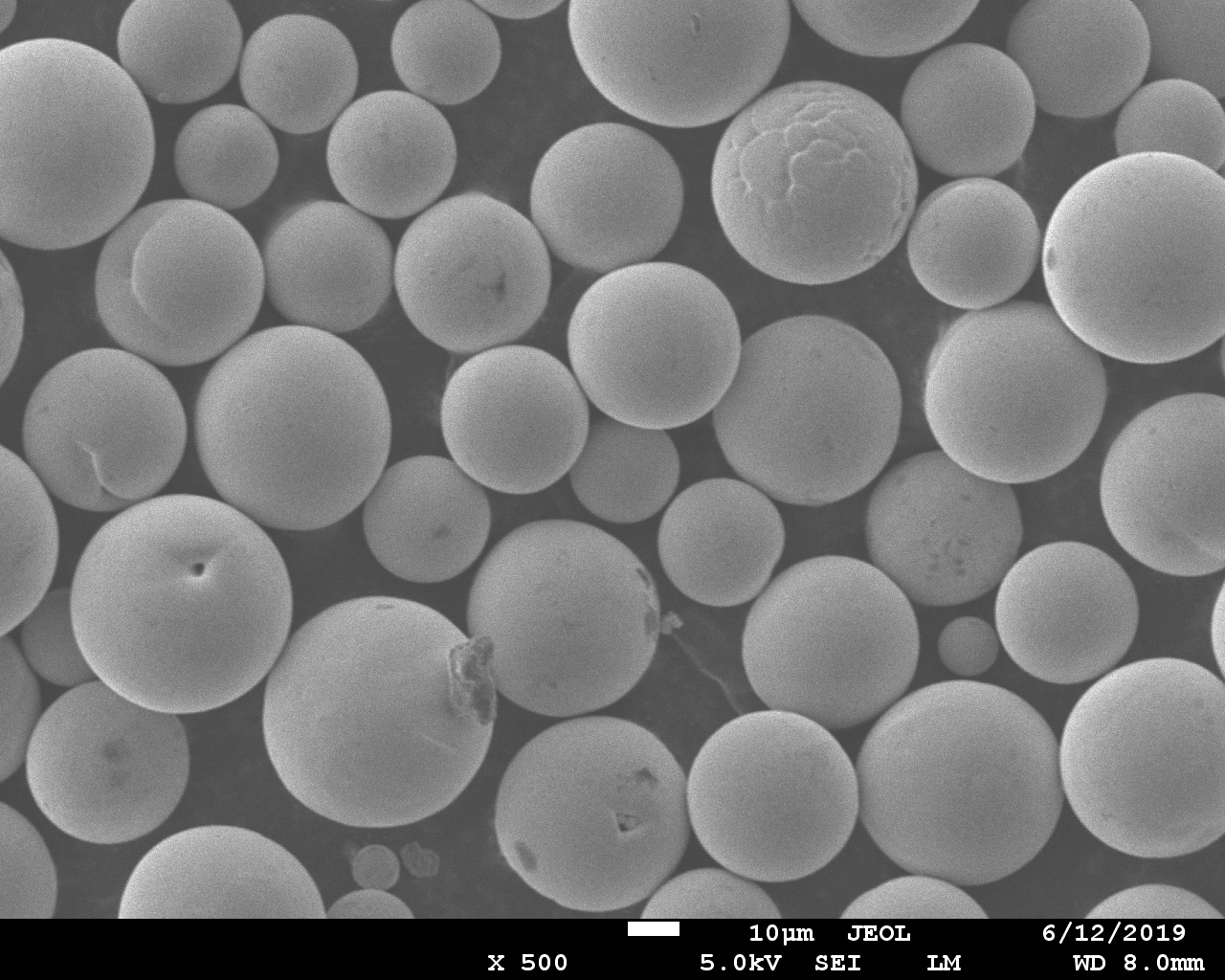

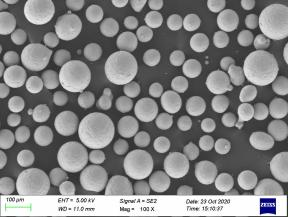

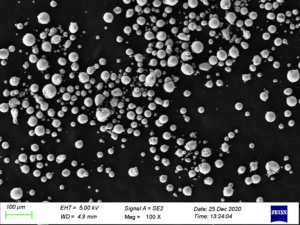

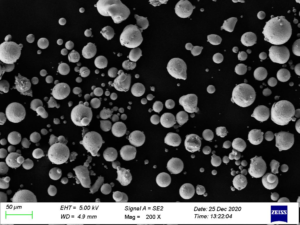

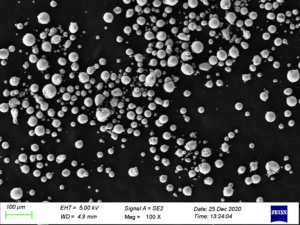

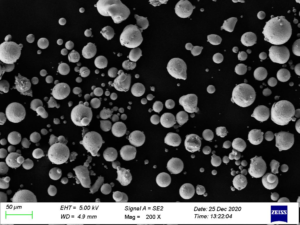

3. 분말 SEM 형태 사진

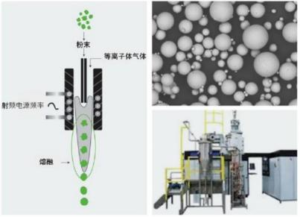

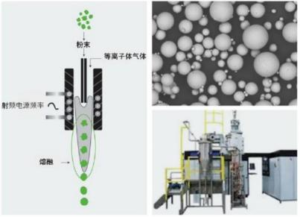

프로덕션 및 테스트 사진:

프로덕션 및 테스트 사진:

4.애플리케이션

4.애플리케이션

- GH5188 has excellent formability, welding and other process properties, making it suitable for manufacturing parts for aircraft engines that require high strength below 980 ℃ and anti-oxidation below 1000 ℃. In the 1980s, GH5188 alloy was applied to components such as vortex plates and flame deflectors in turboshaft eight aircraft engines. Currently, some aircraft engines use GH5188 alloy sheets to prepare high-temperature components such as combustion chamber walls, outer walls, and sealing plates.

프로덕션 및 테스트 사진:

프로덕션 및 테스트 사진:

4.애플리케이션

4.애플리케이션