Potassium titanate whiskers

Caractéristiques du produit:

Potassium titanate whisker products are manufactured using special processes, with uniform thickness, adjustable and controllable size, and significantly better main performance indicators than similar products at home and abroad. Potassium titanate whiskers are a high-performance reinforcing fiber.

| Nom de la marque | Jinchun |

| Origine | Chine |

| Nom du produit | Potassium titanate whiskers |

| Application | brake pads and other friction materials, plastic modification, rubber modification |

| Forme | Solid |

| Couleur | White |

| Taille | Can be booked according to customer needs |

| Standard | GB/T 19001-2016/ISO9001 : 2015 |

| La pureté | Depending on the preparation method |

| Matériau | |

| Emballage | Carton |

DÉTAILS DU PRODUIT

DÉTAILS DU PRODUIT

Caractère du produit

Potassium titanate whisker products are manufactured using special processes, with uniform thickness, adjustable and controllable size, and significantly better main performance indicators than similar products at home and abroad. Potassium titanate whiskers are a high-performance reinforcing fiber.

2. cahier des charges

Potassium titanate whiskers

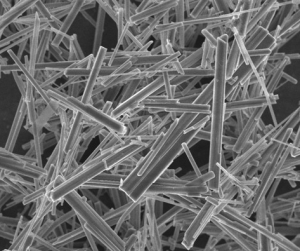

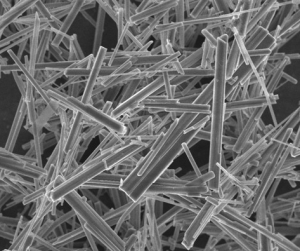

3.Pictures of Powder

Photos de la production et des essais :

Photos de la production et des essais :

4.Application

Main application scope: brake pads and other friction materials, plastic modification, rubber modification, conductive and anti-static materials, high-end coatings, and special coatings with anti-static needs, etc.

Asbestos free friction material

1.Core function: Improve the high-temperature friction stability of the friction plate, reduce wear, reduce braking noise, avoid scratches on the mating parts, and have low density, which is conducive to lightweight braking components.

2.Suitable for high temperature, high pressure, and high load working conditions, used as friction lining for construction machinery (excavators, cranes), rail transit (high-speed rail/subway brake pads), aerospace, as well as heavy-duty friction blocks for mining machinery and metallurgical equipment.

Metal based/ceramic based composite materials

1.The whisker reinforced light alloy prepared mainly enhances light alloys such as aluminum, magnesium, and titanium, with significantly improved specific strength and modulus, excellent wear resistance and fatigue resistance, and a much lower density than traditional steel components.

2.Enhance ceramics such as alumina, zirconia, and silicon carbide to improve their toughness and thermal shock resistance (fracture toughness increased by over 60%), reduce high-temperature creep, while retaining the high-temperature and corrosion resistance properties of the ceramics.

Wear resistant coating/coating

1.Composite with epoxy resin, polyurethane, and organosilicon to prepare workshop floor coatings, engineering machinery surface protective coatings, and mining equipment wear-resistant coatings. The wear resistance of the coatings is 2-3 times higher than that of ordinary coatings, and they are applied to the inner walls of silos/chutes in cement plants and mines, as well as the body protection of excavators and loaders.

2.Composite with ceramic based adhesive to prepare high-temperature equipment wear-resistant coating, applied to the inner walls of industrial kilns, power plant boiler pipelines, and automobile exhaust pipes, balancing insulation and wear resistance, and extending equipment service life.

Sealing and lubricating materials

1.Solid lubricants are prepared by combining potassium titanate whiskers with graphite and molybdenum disulfide. The whiskers form a supporting lubricating film, solving the problem of “high temperature failure and low load capacity” of traditional solid lubricants. It is suitable for lubrication of high temperature and high pressure equipment above 300 ℃, such as metallurgical furnace rollers, steam turbine bearings, and aviation engine parts

2.Ultra fine potassium titanate whiskers (aspect ratio of 10-20) are added to lithium based and polyurea based lubricants to enhance their high temperature resistance and extreme pressure resistance. They are used for lubrication of automotive wheel hub bearings and engineering machinery gearboxes.

4.Application

Main application scope: brake pads and other friction materials, plastic modification, rubber modification, conductive and anti-static materials, high-end coatings, and special coatings with anti-static needs, etc.

Asbestos free friction material

1.Core function: Improve the high-temperature friction stability of the friction plate, reduce wear, reduce braking noise, avoid scratches on the mating parts, and have low density, which is conducive to lightweight braking components.

2.Suitable for high temperature, high pressure, and high load working conditions, used as friction lining for construction machinery (excavators, cranes), rail transit (high-speed rail/subway brake pads), aerospace, as well as heavy-duty friction blocks for mining machinery and metallurgical equipment.

Metal based/ceramic based composite materials

1.The whisker reinforced light alloy prepared mainly enhances light alloys such as aluminum, magnesium, and titanium, with significantly improved specific strength and modulus, excellent wear resistance and fatigue resistance, and a much lower density than traditional steel components.

2.Enhance ceramics such as alumina, zirconia, and silicon carbide to improve their toughness and thermal shock resistance (fracture toughness increased by over 60%), reduce high-temperature creep, while retaining the high-temperature and corrosion resistance properties of the ceramics.

Wear resistant coating/coating

1.Composite with epoxy resin, polyurethane, and organosilicon to prepare workshop floor coatings, engineering machinery surface protective coatings, and mining equipment wear-resistant coatings. The wear resistance of the coatings is 2-3 times higher than that of ordinary coatings, and they are applied to the inner walls of silos/chutes in cement plants and mines, as well as the body protection of excavators and loaders.

2.Composite with ceramic based adhesive to prepare high-temperature equipment wear-resistant coating, applied to the inner walls of industrial kilns, power plant boiler pipelines, and automobile exhaust pipes, balancing insulation and wear resistance, and extending equipment service life.

Sealing and lubricating materials

1.Solid lubricants are prepared by combining potassium titanate whiskers with graphite and molybdenum disulfide. The whiskers form a supporting lubricating film, solving the problem of “high temperature failure and low load capacity” of traditional solid lubricants. It is suitable for lubrication of high temperature and high pressure equipment above 300 ℃, such as metallurgical furnace rollers, steam turbine bearings, and aviation engine parts

2.Ultra fine potassium titanate whiskers (aspect ratio of 10-20) are added to lithium based and polyurea based lubricants to enhance their high temperature resistance and extreme pressure resistance. They are used for lubrication of automotive wheel hub bearings and engineering machinery gearboxes.

| Nom/ Type | diameter | length |

| 钛酸钾晶须 | 0.2~0.5μm | 0.1~0.3μm |

| 5~15μm | 3~5μm |

Photos de la production et des essais :

Photos de la production et des essais :

4.Application

Main application scope: brake pads and other friction materials, plastic modification, rubber modification, conductive and anti-static materials, high-end coatings, and special coatings with anti-static needs, etc.

Asbestos free friction material

1.Core function: Improve the high-temperature friction stability of the friction plate, reduce wear, reduce braking noise, avoid scratches on the mating parts, and have low density, which is conducive to lightweight braking components.

2.Suitable for high temperature, high pressure, and high load working conditions, used as friction lining for construction machinery (excavators, cranes), rail transit (high-speed rail/subway brake pads), aerospace, as well as heavy-duty friction blocks for mining machinery and metallurgical equipment.

Metal based/ceramic based composite materials

1.The whisker reinforced light alloy prepared mainly enhances light alloys such as aluminum, magnesium, and titanium, with significantly improved specific strength and modulus, excellent wear resistance and fatigue resistance, and a much lower density than traditional steel components.

2.Enhance ceramics such as alumina, zirconia, and silicon carbide to improve their toughness and thermal shock resistance (fracture toughness increased by over 60%), reduce high-temperature creep, while retaining the high-temperature and corrosion resistance properties of the ceramics.

Wear resistant coating/coating

1.Composite with epoxy resin, polyurethane, and organosilicon to prepare workshop floor coatings, engineering machinery surface protective coatings, and mining equipment wear-resistant coatings. The wear resistance of the coatings is 2-3 times higher than that of ordinary coatings, and they are applied to the inner walls of silos/chutes in cement plants and mines, as well as the body protection of excavators and loaders.

2.Composite with ceramic based adhesive to prepare high-temperature equipment wear-resistant coating, applied to the inner walls of industrial kilns, power plant boiler pipelines, and automobile exhaust pipes, balancing insulation and wear resistance, and extending equipment service life.

Sealing and lubricating materials

1.Solid lubricants are prepared by combining potassium titanate whiskers with graphite and molybdenum disulfide. The whiskers form a supporting lubricating film, solving the problem of “high temperature failure and low load capacity” of traditional solid lubricants. It is suitable for lubrication of high temperature and high pressure equipment above 300 ℃, such as metallurgical furnace rollers, steam turbine bearings, and aviation engine parts

2.Ultra fine potassium titanate whiskers (aspect ratio of 10-20) are added to lithium based and polyurea based lubricants to enhance their high temperature resistance and extreme pressure resistance. They are used for lubrication of automotive wheel hub bearings and engineering machinery gearboxes.

4.Application

Main application scope: brake pads and other friction materials, plastic modification, rubber modification, conductive and anti-static materials, high-end coatings, and special coatings with anti-static needs, etc.

Asbestos free friction material

1.Core function: Improve the high-temperature friction stability of the friction plate, reduce wear, reduce braking noise, avoid scratches on the mating parts, and have low density, which is conducive to lightweight braking components.

2.Suitable for high temperature, high pressure, and high load working conditions, used as friction lining for construction machinery (excavators, cranes), rail transit (high-speed rail/subway brake pads), aerospace, as well as heavy-duty friction blocks for mining machinery and metallurgical equipment.

Metal based/ceramic based composite materials

1.The whisker reinforced light alloy prepared mainly enhances light alloys such as aluminum, magnesium, and titanium, with significantly improved specific strength and modulus, excellent wear resistance and fatigue resistance, and a much lower density than traditional steel components.

2.Enhance ceramics such as alumina, zirconia, and silicon carbide to improve their toughness and thermal shock resistance (fracture toughness increased by over 60%), reduce high-temperature creep, while retaining the high-temperature and corrosion resistance properties of the ceramics.

Wear resistant coating/coating

1.Composite with epoxy resin, polyurethane, and organosilicon to prepare workshop floor coatings, engineering machinery surface protective coatings, and mining equipment wear-resistant coatings. The wear resistance of the coatings is 2-3 times higher than that of ordinary coatings, and they are applied to the inner walls of silos/chutes in cement plants and mines, as well as the body protection of excavators and loaders.

2.Composite with ceramic based adhesive to prepare high-temperature equipment wear-resistant coating, applied to the inner walls of industrial kilns, power plant boiler pipelines, and automobile exhaust pipes, balancing insulation and wear resistance, and extending equipment service life.

Sealing and lubricating materials

1.Solid lubricants are prepared by combining potassium titanate whiskers with graphite and molybdenum disulfide. The whiskers form a supporting lubricating film, solving the problem of “high temperature failure and low load capacity” of traditional solid lubricants. It is suitable for lubrication of high temperature and high pressure equipment above 300 ℃, such as metallurgical furnace rollers, steam turbine bearings, and aviation engine parts

2.Ultra fine potassium titanate whiskers (aspect ratio of 10-20) are added to lithium based and polyurea based lubricants to enhance their high temperature resistance and extreme pressure resistance. They are used for lubrication of automotive wheel hub bearings and engineering machinery gearboxes.